Detectors: up to 4 shielded plastic scintillators

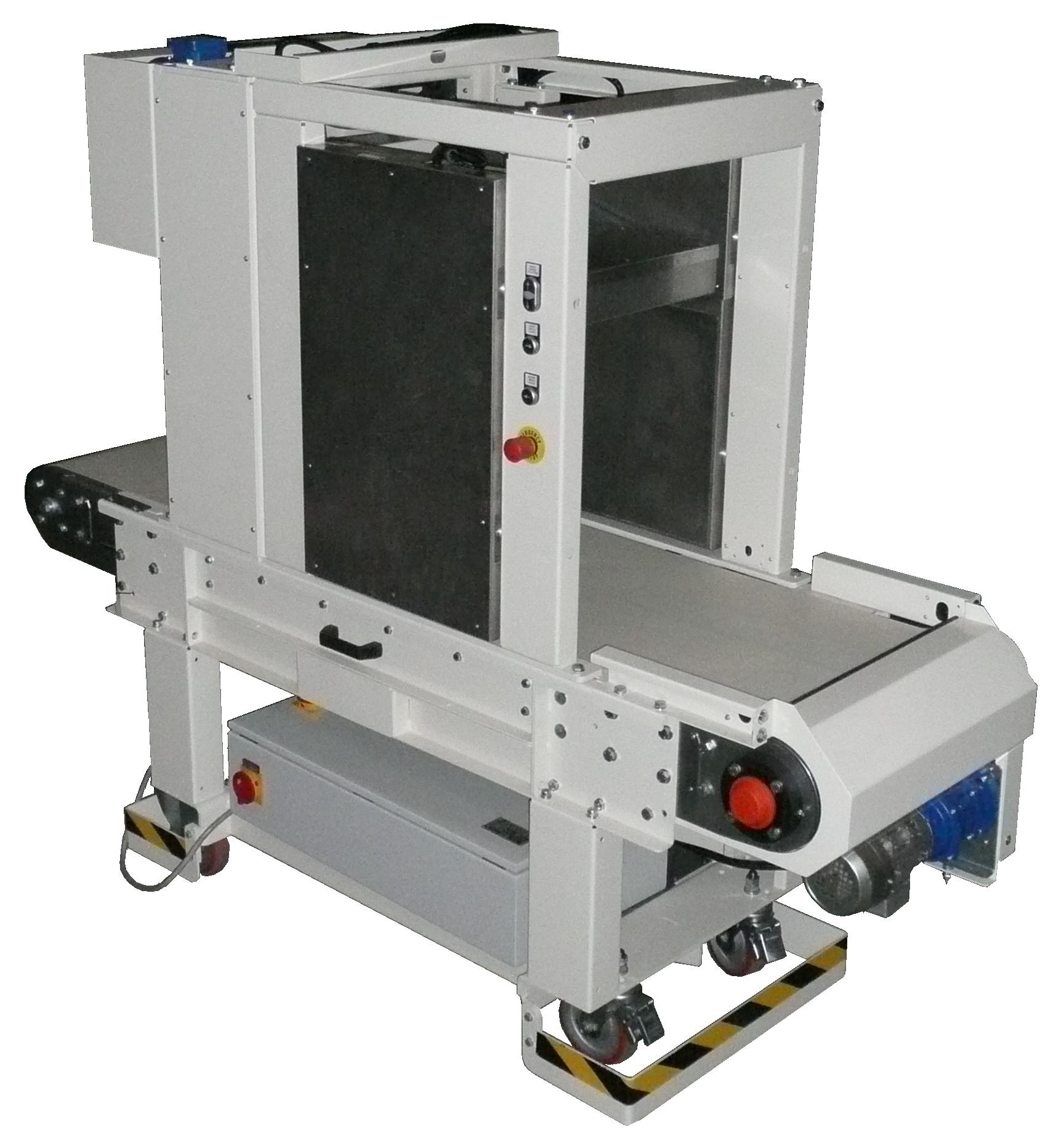

Movable upper detector along vertical axis

Wheel-mounted frame

Automatic, photocell-surveyed monitoring cycle

MDA (Co-60): 200 Bq (10 s)

The CARONTE gamma contamination monitor is designed to easily measure the radioactivity level of small objects, such as boxes, tools or laundry bags, transported across a measurement area by a conveyor belt.

The scanning cycle and the measurement procedure are entirely controlled by the software installed on the control PC, which manages the PLC commands sequence.

The materials to be monitored are placed on one side of the conveyor belt, which is constantly moving, and a set of photocells allows the software to know the object position and properly manage the scanning steps. A static, operator-guided mode is also available.

At the end of each scanning sequence, if the pre-set alarm thresholds are exceeded, a proper visual and acoustic indication will be activated.

The automatic cycle includes the following steps:

The cycle is then automatically resumed; if the object is longer than the measurement area, consecutive steps are performed until the entire length of the object is scanned.